CECOTM NON-METALLIC & COMPOSITE FLEXIBLE EXPANSION JOINTS

CECOTM NON-METALLIC & COMPOSITE FLEXIBLE EXPANSION JOINTS

The CECOTM non-metallic and composite flexible expansion joints for piping and rigid ducting for use in environmental control systems used in industrial applications.

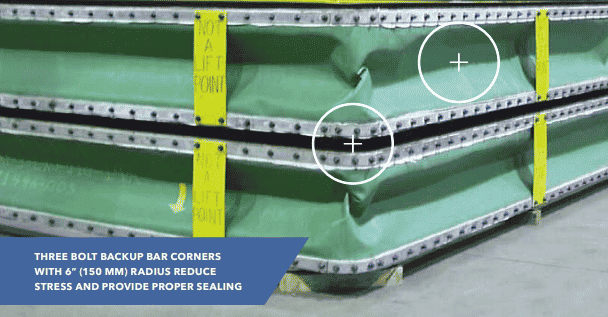

COMPOSITE EXPANSION JOINTS

Expansion joints are used to provide a point of flexibility in flue ducts, and to relieve stress caused by system movement. A composite expansion joint consists of layers of material bounded, sewn or mechanically fastened together along the edges. Each layer of material is designed to function independently of the others.

Our CECOTM Composite Expansion Joints are engineered to deliver optimal performance and efficiency. With temperature applications from 600°F to in excess of 1500°F, and an outer later material consisting of woven fiberglass and fluoropolymer resins for chemical resistance, we confidently deliver durable and reliable solutions, while meeting your specific application needs and environmental standards.

Benefits of Non-Metallic and Composite Flexible Expansion Joints

- Low Total Cost of Ownership

- Lower material costs

- Minimal shipping and installation costs

- High reliable solution for temperature applications from 600°F to 1500°F

- Optimal durability due to our chemical resistant outer later material

Features of Non-Metallic and Composite Flexible Expansion Joints

- 6 durable layers for expansion joint maximum performance

- Outside cover layer – fluoropolymer material which can operate in the flue duct atmosphere, and serves a gas seal

- TFE layer – a sheet of skived PTFE that is highly resistant to chemicals and functions as a vapor (gas) barrier

- Fiberglass / Cloth layer – Vermiculite coated fiberglass fabric acts as an insulator and provides expansion joint durability and strength

- Insulation layer – protects the cover and the vapor barrier from heat degradation

- Fiberglass / Cloth layer – Vermiculite coated fiberglass fabric acts as an insulator and provides expansion joint durability and strength

- Inside Layer / Tube – Close weave material binds the belt together, acts as an insulator and gives the belt a finished appearance.

Contact Us

North and South America

14651 Dallas Parkway

Suite 500

Dallas, TX 75254

USA Phone: 214-357-6181

Fax: 214-351-0194

Toll Free: 800-333-5475

Europe

Industrieweg 59

P.O. Box 65

8070AB Nunspeet

The Netherlands

Phone: +31 341 252 635

Fax: +31 341 262 112

Middle East and Africa

AU Gold Tower, Floor 28, Office A Cluster I

Jumeirah Lake Towers

PO Box 62435

Dubai, United Arab Emirates

Phone: +971 (0) 4434 0004

Fax: + 971 (0) 4434 0666

Asia

Suite 810, Building B International Venture Park

No. 2679 Hechuan Road

Minhang District

Shanghai, 201103

China

Phone: +86-21-58248000

Fax: +86-21-58249697