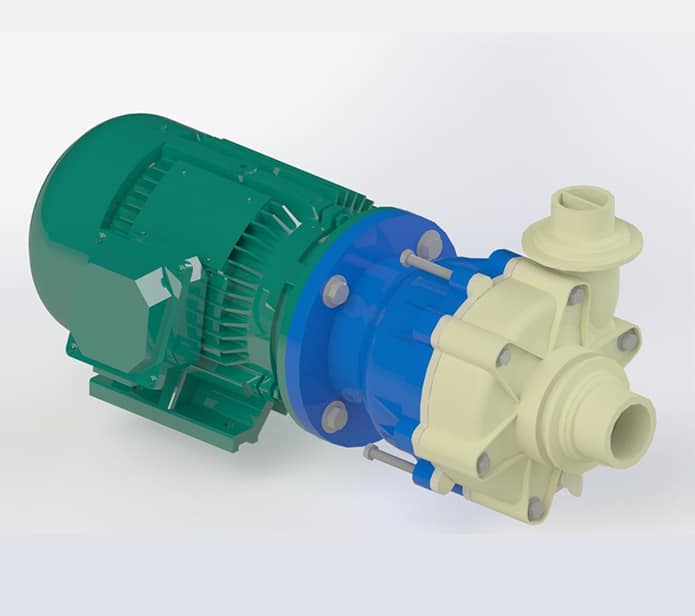

Our Sethco Magnetic Drive End Suction Pumps are precision designed to meet the demands of a wide range of OEM (Original equipment manufacturers), chemical and industrial applications. These pumps can be used for highly corrosive or mild chemicals, acids, or solvents. Their simple efficient design provides reliable, trouble-free performance and easy maintenance.

Sethco offers a diverse selection of top-quality pumps for use in multiple industries. Experts in the finishing and electronics industries have found that Sethco pumps are reliable from the outset when dealing with corrosive and hazardous chemicals. When it comes to dependability, Sethco is the industry standard.

As a global leader, Sethco builds pumps that have an outstanding reputation. When transporting or disposing of seawater, acids, high temperature liquids, brines, caustics, bleaches, or any other dangerous liquids, our powerful pumps can handle the job. Magnetic Drive End Suction Pumps are corrosion resistant and expertly crafted. That is why desalination, petrochemical, wastewater treatment, metal finishing, and aquarium businesses worldwide trust Sethco pumps. When it moves through a Sethco pump, it exits when and where you expect.

Transporting hazardous chemicals or liquids using substandard pumps can lead to contact with materials that can be perilous to the health of you and your employees. Do not take that chance. Sethco pumps give you peace of mind knowing that the contaminants are safely contained. Contact us if you are faced with any concerns, our expert staff is there to help you. The quality employees at Sethco make and support quality products. Let Sethco become a valuable part of your business today.

Features & Benefits

- Stainless steel exterior hardware

- Capacities to 250 GPM (59 m3/hr)

- Heads to 94 feet (29 m)

- Powers to 10 HP (7.5 kW)

- Temperatures to 210°F (99°C)

- Optional FRP (Fiberglass Reinforced Polymer) baseplates

- Polypropylene or Kynar® construction

- One-piece stationary ceramic shaft

- Carbon or silicon carbide bearings

- Two-piece impeller design

- TEFC motors

- Low Total Cost of Ownership

- Sealless design – magnetic drive

- High strength – molded one piece casing and rare earth magnets

- Easy maintenance

- 25 models available

- Acids

- Bleaches

- Caustics

- Chemical Transfer

- Cleaning/Mixing

- Filtration

- Ideal for OEMs (Original equipment manufacturers)

- Processing

- Recirculation

- Reverse Osmosis

- Scrubber

- Seawater

- Solvents

- Wastewater

- Agricultural/Aquariums

Telford, PA, USA

Phone: +1 215-723-8155

Toll Free: (800) 392-7621