Peerless Dissolved Gas Flotation units utilize a recirculation pump system to introduce micro-bubbles, enhancing the separation surface area improving the oil and solid separation performance. The Peerless DGF has a sophisticated pumping mechanism to generate micro-bubbles.

These pumps utilize dual sided impellers to draw in vapor and precisely mix it with the liquid. The vapor/ liquid mixture is sheared and compressed in the pump to enhance creation of micro-bubbles before this gas- enriched mixture is depressurized and discharged to the flotation chamber. The dense bubble formation lifts oils and solids to the liquid surface where they are ultimately skimmed off and discharged.

This configuration eliminates the need for a separate dissolution vessel as found on many traditional dissolved air flotation systems. Further simplification is realized as complicated back pressure and level control setups are no longer required.

Principle of Operation

In the Dissolved Gas flotation (DGF) process, the micro-size gas bubbles are generated by saturating a pressurized partial stream of treated water with gas and subsequently releasing this stream to atmospheric pressure. This is contrary to the traditional process of Induced Gas Flotation, whereby gas is drawn straight from the blanketing gas cap and is introduced into the raw water solely by mechanical means such as impellers, jet nozzles or venturi devices.

The Dissolved Gas Flotation process produces much finer bubbles than the traditional induced air flotation allowing for much higher separation efficiencies.

Oil is typically present in the form of a finely dispersed emulsion which creates a significant separation challenge. Employing a properly designed DGF system, along with chemical treatment, brings an effective systematic approach.

Features & Benefits

- Enhanced separation over traditional flotation systems down to 10 ppm concentration of free oil in water

- High contaminant removal efficiency due to smaller bubble size of denser bubble population

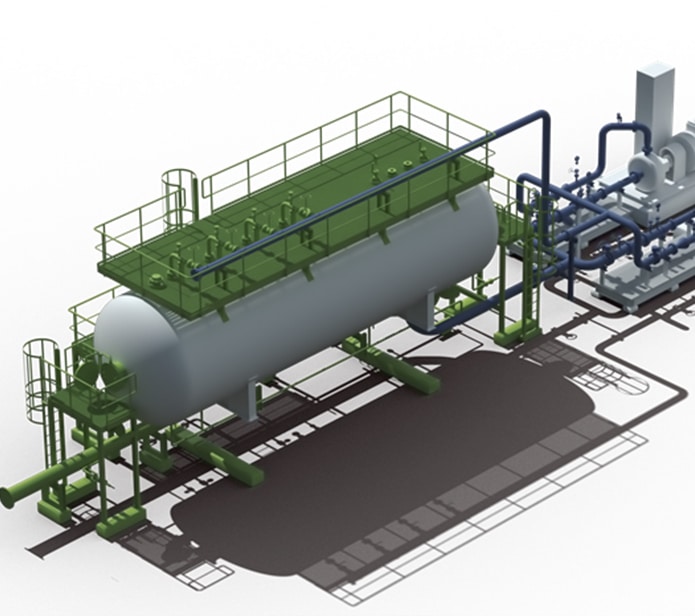

- Easy maintenance and minimum operation cost with the removal of the conventional pressurized dissolution vessel

- Small footprint with compact structure

- Reduced fuel gas consumption

- Offshore – Mobile Offshore Production units (MOPU), FPSO Topsides

- Onshore – Oil and Gas Processing Facilities, Early Production Facilities (EPF)

- Refineries & Petrochemical

- Produced Water Reinjection

Dallas, TX, USA

Phone: 214-357-6181

Elma, NY, USA

Phone: 716-662-6540

Stansted, Essex, United Kingdom

Phone: +44-1439-330623

Dubai, United Arab Emirates

Phone: +971 (0) 4434 0004

Singapore

Phone: +65-6472-0020

Shanghai, China

Phone: +86-21-62560387