The oily water enters the corrugated plate interceptor via a specially designed slotted cross pipe that distributes the flow over the width of the separator basin. Due to the sudden decrease of flow velocity, a certain number of solids that may be contained in the liquid will settle in the inlet compartment. Depending on the solid’s concentration, a sludge suction device may be included in the design for intermittent removal of accumulated solids.

The oily water continues its way towards the plate packs wall and enters the plate pack from the top on a counter-flow direction. In the laminar flow in each channel (i.e., the distance between two subsequent plates), the minute oil droplets rise by their density is lower than that of the carrier medium and attach themselves to the underside of the upper plate.

The build-up oily layer that is thus constantly being formed at the underside of each plate creeps slowly upwards. The oil film is assisted in its upward movement by the counter-current laminar flow.

At the top of each plate the oil film is concentrated (coalesced) by the plates and leaves the plate at the ‘highest point’ as a thick stream or rising chain of large globules.

The treated water flows through the overflow baffle between the plates towards the outlet; thus, there is no interference between the separated oil and the clean water. The separated oil collects as a layer on top of the liquid surface and can be removed intermittently via the adjustable oil skimmer.

Features & Benefits

All Skim-CKS Separator internals are of robust construction designed for many years of maintenance free operation. Depending on the properties of the liquid to be treated the material of the inclined plate packs can be:

- Glass fibre reinforced polyester (GRP)

- Coated carbon steel

- Various grades of Austenitic Steel (SS304, SS316, DSS, SDSS)

- Teflon-coated steel

Depending on the concentration of suspended solids, or oil, the plate spacing can be varied to suit the specific process conditions. Thus, we can offer to our clients the technically optimized solution for each individual application.

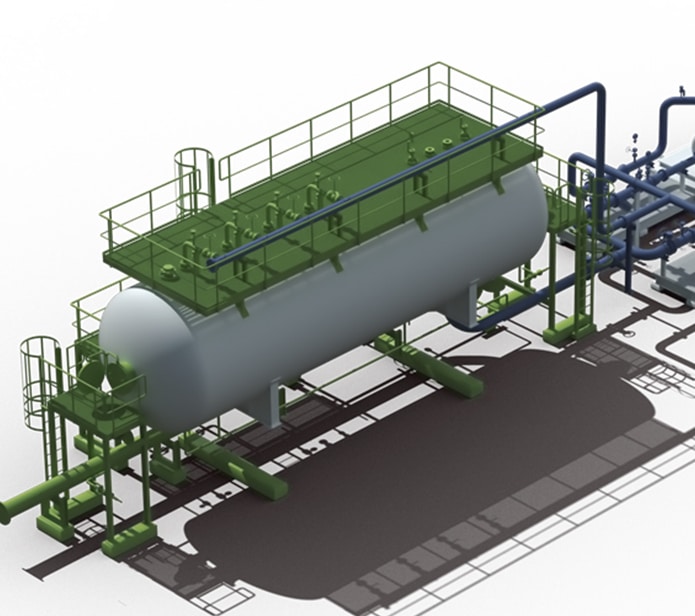

The Corrugated Plate Interceptors in Concrete Basin (Skim-CKS) design is for below ground installation, applicable to a wide variety of treatment problems at atmospheric pressure:

- Produced water

- Drains water

- Deballast water

- Oily surface drain water

- Refinery effluent

- Process water/Desalter effluent

Dallas, TX, USA

Phone: 214-357-6181

Elma, NY, USA

Phone: 716-662-6540

Stansted, Essex, United Kingdom

Phone: +44-1439-330623

Dubai, United Arab Emirates

Phone: +971 (0) 4434 0004

Singapore

Phone: +65-6472-0020

Shanghai, China

Phone: +86-21-62560387