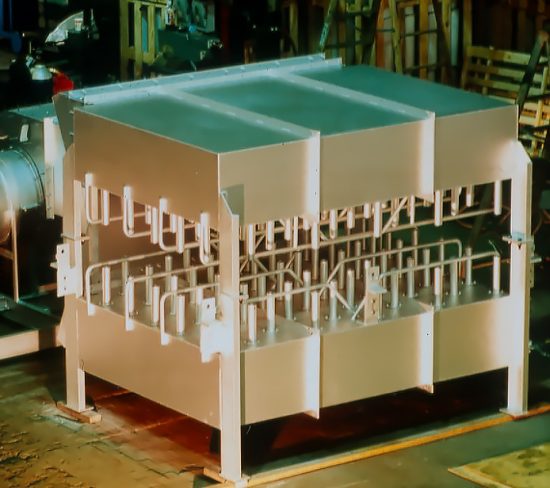

Mist Eliminator Model HPE

Mist Eliminators are designed to separate liquids from gas or vapor flow, effectively reducing condensate solids emission. Our HEE-Duall HPE Series Mist Eliminator operates utilizing direct compaction combined with centrifugal force to remove liquid entrainment from exhaust streams, thereby ensuring maximum performance and durability at minimal investment cost.

For nearly fifty years, the HEE-Duall has led the world in the fabrication of purification products. Our state-of-the-art technology is designed to manage dangerous and volatile exhaust compounds across a range of industries. Our diverse product line includes everything needed to handle the collection, management, and control of corrosive gases, airstreams, mists, and vapors. Our HPE Series Mist Eliminator excel at removing liquid contaminants from industrial exhaust streams, preventing damage to equipment and the environment. When you use HEE-Duall products, you can rest assured that your exhaust streams are effectively and efficiently cleaned.

FEATURES & BENEFITS

- 18 standard sizes and capacities to 40,000 ACFM

- Patented profile mist eliminator blades

- Easy maintenance and cleaning

- High velocity design for a smaller footprint

- Corrosion-resistant for long life

- Removes 10-to-3-micron droplets with optional mesh pad

- One piece construction for leak-free operation

- Low Total Cost of Ownership

- Optimal efficiency – Greater than 99% removal efficiency

- Energy savings due to low pressure loss

- High value and high reliability – Constructed of premium polyester resin to assure superior corrosion resistance for a wide variety of chemical applications

APPLICATIONS

With years of delivering quality systems with maximum efficiency, easy maintenance and high reliability, we can custom-design our packages to fit your needs for specialty applications:

- Circuit board manufacturing

- Chemical manufacturing and processing

- Metal plating and finishing

- Power plants

- Battery manufacturing