High Efficiency, Uniform Drying, Stable Operation

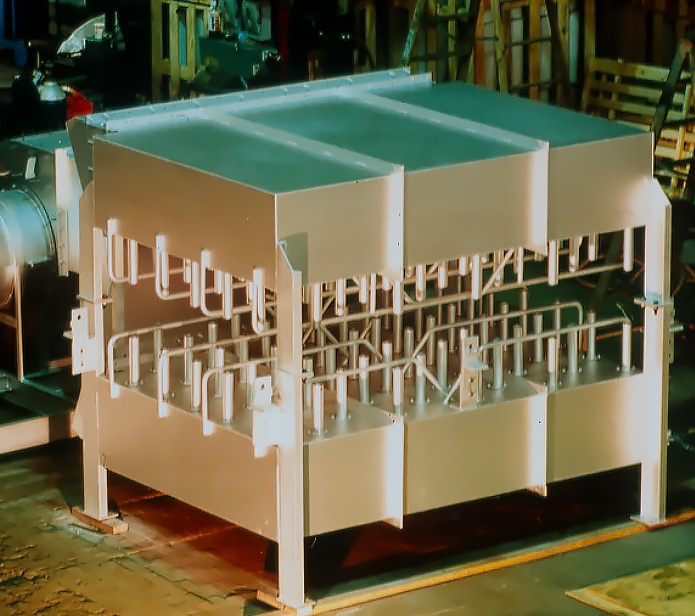

The Busch JET* STAR™ Strip Drying System uses high volume, low pressure heated air to rapidly dry moving metal strips. The JET* STAR™ Strip Dryers produce predetermined functional wiping patterns on the strip surface. Air flow and thermal energies are applied in an intensive and uniform manner, resulting in rapid water disengagement and almost instantaneous mist removal from the strip. Spent heat is dissipated in the dryer, thus reducing re-deposition of airborne fog and mist.

JET* STAR™’s uniformity and repeatability of the drying process across and along the strip enhances:

- Film disengagement

- Mist transportation

- Evaporation

Problems associated with recirculated systems such as the buildup of CO2, CO, humidity, temperature, and corrosion are substantially eliminated.

JET* STAR™ strip dryers are designed using centrifugal fans with backwardly curved wheels which consume less horsepower and create less noise compared to other designs. Most JET* STAR™ Strip Drying Systems consists of a supply air fan, connecting duct, floe control dampers, air heater, and the JET* STAR™ Strip Dryer. Steam or natural gas-fired heating systems are available.

Features & Benefits

- Low Total Cost of Ownership

- Extremely flexible – ease of adjustment of size and velocity of the dryers ambient and/or hot zones

- Designed using centrifugal fans that consume less horsepower and create less noise

- High value and quality materials – constructed with heavy gauge carbon steel duct and plenum construction

- Maximum efficiency with Jet*Star technology

- Applicable to all types of process lines

- Jet*Star also available in an Air/Water configuration

- Variable speed drives

- Alternate paint systems

- Horizontal or vertical arrangement

- Support steel and platforms

- Exhaust fans

- Thermal or sound insulation

- Filters for outside air

- Temperature measurement device

- Gas or steam heat source

- Stainless steel nozzles

JET* STAR™ Systems are extremely flexible. The design allows for size and velocity adjustments of the dryer’s ambient and hot zones specific to each application.

- Steam or gas fired heating

- Alternate paint systems and material of construction

- Horizontal or vertical arrangement

- Support steel and platforms

- Exhaust fans

- Thermal or sound insulation

- Filters for supply air

- Temperature measurement device

- Stainless steel nozzles

- Built-in support rolls

Wexford, PA, USA

Phone: 724-940-2326

Nunspeet, The Netherlands

Phone: +31-341-252-635