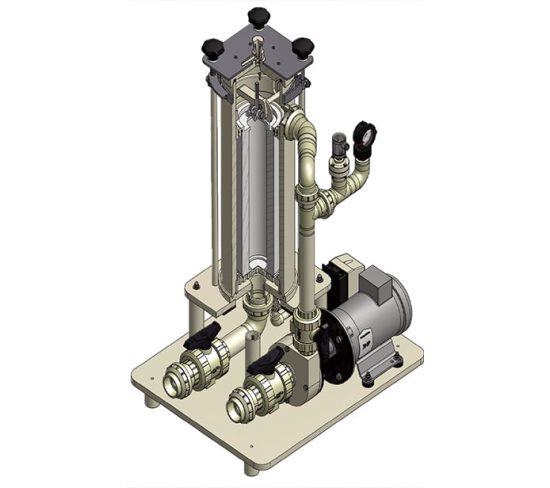

PP Series – Polypropylene Electroplating Filter Systems – 7000/9000 PP Series

Our Mefiag dual chamber Polypropylene Electroplating Filter Systems feature horizontal disc technology and have capacities from 7,000 to 9,000 gph.

Founded in 1953, Mefiag has succeeded in becoming a global leader in the development, creation, and distribution of unsurpassed filter solutions. Our advanced filtration and pump solutions lead the field in the plating, anodizing, and metal finishing industries. Mefiag products stand up to the toughest conditions. Mefiag filters are designed to work harder.

Mefiag products are the most versatile on the market. Beyond our filtration systems for electroplating, our pump and filter products are used in diverse global industries to separate and eliminate harmful substances. As our capability has expanded, one thing has never changed: our commitment to providing reliable, efficient products. When you choose a Mefiag filtration system for your business, you are choosing peace of mind.

At Mefiag, we are proud of our heritage. From the very beginning, we have been committed to manufacturing the best products for the best people. If your goal is reliability and excellence, then you can trust Mefiag to bring your company the filtering solution that delivers. For the optimum in filtration, choose Mefiag.

FEATURES & BENEFITS

- Designed for the filtration of nickel, copper, and zinc electrolytes

- Operating temperature to 180°F (82°C)

- Capacities range from 7,000 to 9,000 gph (442 to 568 L per minute)

- For plating tanks from 400 to 1,000 gallons (1818 to 4546 L) depending on the type of process

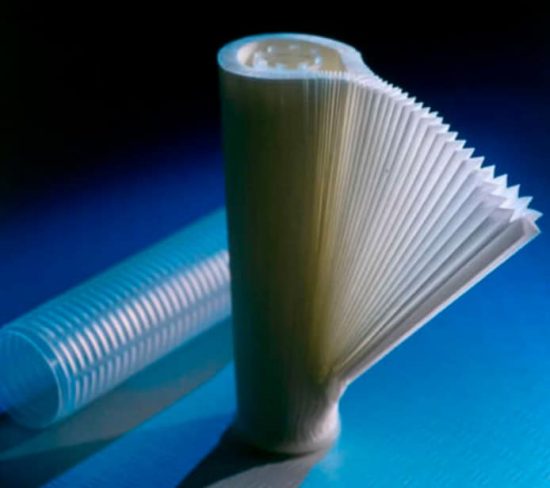

- Can be supplied with horizontal discs or cartridges depending on the application

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

APPLICATIONS

- Automotive

- Construction

- Sanitary

- Plating

- Anodizing

- Metal Finishing

- Labs

- Small Plating Tanks