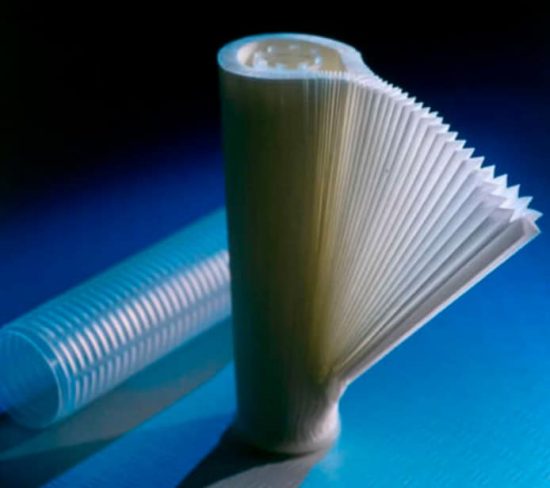

String Wound Cotton Depth Filter Cartridges

Mefiag String Wound Cotton Depth Filter Cartridges are fabricated of natural or synthetic fiber wound over a perforated plastic or metal core. The precision winding pattern covers the entire depth of the filter tube with hundreds of funnel-shaped tunnels which become gradually finer from the outer surface to the center of the tube and trap progressively finer particles as the fluid travels to the center. This allows much greater solids retention capacity than is associated with surface filter media of the same dimensions.

Mefiag provides top-quality pumps and filter cartridges for use in several applications. When dealing with corrosive and hazardous chemicals in various industries, experts trust Mefiag filter cartridges to be reliable and efficient as soon as they are installed. Mefiag sets the industry standard when it comes to dependability.

Mefiag products have an excellent reputation. If you need to filter acids, alkalis, or any other hazardous liquids, our cartridge filters will handle the job. The precision winding patterns of our String Wound Cotton Depth Filter Cartridges trap progressively finer particles as the fluids transverse toward the center of the cartridge. Businesses all over the world trust Mefiag cartridge filters.

Substandard filters can leave contaminants behind. Do not rely on inferior cartridges for your filtration needs. Go with Mefiag and get peace of mind. Our expert engineering staff will be there to help you make the right selection. Let Mefiag become a valuable part of your business today.

FEATURES & BENEFITS

- Standard sizes

- Specifically designed for corrosion resistant service

- High flow rate – low pressure drop

- High efficiency

- High solids holding capacity

- Simple to use – easy to replace

- Economical

- Low Total Cost of Ownership

- High flow rate – low pressure drop

- Long service life – high solids holding capacity

- Easy maintenance