In refineries, chemical process plants, compressed air or gas plants, noise and vibration radiated by the piping or ducting network represent a major issue for equipment integrity, workers safety and community relationships.

CECO Burgess-Manning inline suction or discharge silencers are carefully custom engineered to reduce such noise issues for centrifugal compressors, roots blowers, control valves or large fans. Thanks to decades of experience and Burgess Manning legacy, our solutions will both reduce the sound level inside the pipes but also reduce the vibrations and solid-born noise propagation.

Design Principles

Typically, CECO Burgess-Manning inline silencers are divided into:

- Absorptive / Dissipative Silencers

These silencers typically provide a very good broadband noise attenuation. Absorbing material is carefully selected for its acoustical properties and protected from flow erosion by a special fabric and perforated sheets to allow higher flow velocities and limit the size of the silencers.

Absorptive silencers can be provided complete with casing or as cartridges to be inserted into existing customer piping, between two flanges

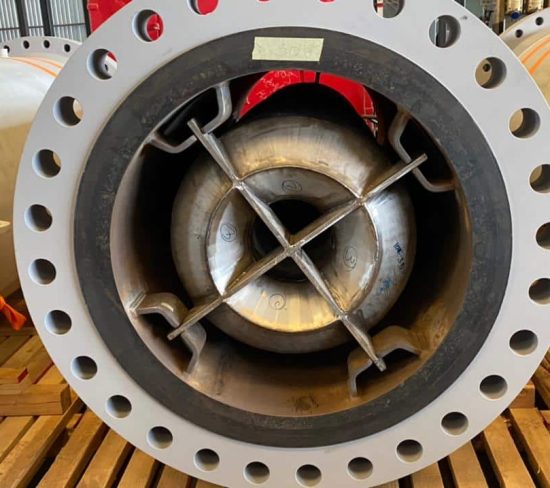

The silencers are made of different chambers and volume which are related by choke tubes or venturis. Reactive silencers can be tuned to address specific noise frequencies and can also treat some of the flow pulsations. They can be 100% reactive (with no acoustic fibers) or combined with an absorptive silencer to achieve a broader noise attenuation

Keywords : inline silencer, reactive silencer, absorptive silencer, dissipative silencer, inline diffuser, compressor silencer, blower silencer, roots silencer, positive displacement compressor silencer, reciprocating compressor silencer, centrifugal compressor silencer, inline valve silencer, screw compressor silencer, pressure drop, pressure silencer