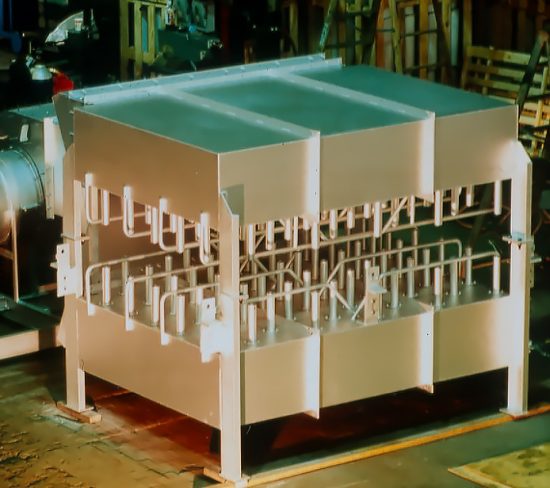

Jumbo Series High Capacity Electroplating Filter Systems

Our Mefiag High Capacity Electroplating Filter System – HF Jumbo Series are single chamber steel rubber lined filter units that feature horizontal disc technology and capacities up to 30,000 gph.

Mefiag LS/HF Series – High Capacity Electroplating Filter Systems: HF Series 30,000 – Jumbo

Established in 1953, Mefiag has become a global leader in developing, creating, and distributing world-class filter systems. Our advanced filtration and pump products lead the market in the plating, metal finishing, and anodizing industries. Our solutions excel in the most severe conditions. Mefiag filters work hard because you do.

Mefiag products are the most versatile on the market. Along with our filtration solutions for electroplating, our pumps and filters are widely used in industries worldwide. Companies use our products to filter and dispose of copper, nickel, and zinc electrolytes reliably and consistently. As our expertise grows, one thing never changes: our steadfast promise to craft reliable and efficient products for our clients. Choose a Mefiag filtration system for your business, and you choose peace of mind.

At Mefiag, we are proud of our roots. From our first day to our last, we strive to supply exceptional products for exceptional businesses. If you seek excellence as we do, then you can rely on Mefiag to bring your company the superiority and dependability it deserves. For the optimum filtration solution, choose Mefiag.

FEATURES & BENEFITS

- Mechanical lifting device for access to filter pack

- Designed for the filtration of nickel, copper, and zinc electrolytes

- Operating temperature to 180° F (82° C)

- For plating tanks to approximately 8,000 gallons (about 30,300 L) depending on the type of process

- Special X-versions of these units are available for filtration of aggressive liquids such as acid copper, acid zinc or acid tin. The slurry tank and filter housing on X-versions are lined inside and out with ebonite, and the pump shaft is titanium

- Low Total Cost of Ownership

- Horizontal disc technology for greater surface area and maximum efficiency

APPLICATIONS

- Automotive

- Construction

- Sanitary

- Plating

- Anodizing

- Metal Finishing

- Labs

- Small Plating Tanks