FCC Cyclones – Reactor

Fluid Catalytic Cracking Units (FCC Cyclones) are the principal technologies that enable the critical process within heavy oil refining of converting the heavy oils into more valuable gasoline and lighter products. More than half of the refinery’s heavy petroleum is processed through the FCC Cyclones, and the FCC Cyclones are also an important source of butene and pentene olefins used in refinery processes.

Our Emtrol-Buell brand has supplied more FCC Cyclones to refineries and petrochemical plants worldwide than any other supplier, so our experience in this area is unequaled. Our FCC Cyclones are designed to enhance separation efficiency, accommodate increased catalyst loading, and are tailored to meet the application needs of refineries and petrochemical plants.

We custom-engineer the following products at the highest quality:

- FCC Cyclones – Patented Beam Hanger Support System

- FCC Cyclones – Reactor

- FCC Cyclones – Regenerator

- FCC Cyclones – Third Stage Separator Systems

- FCC Cyclones – Fourth Stage & Catalyst Hopper Cyclones

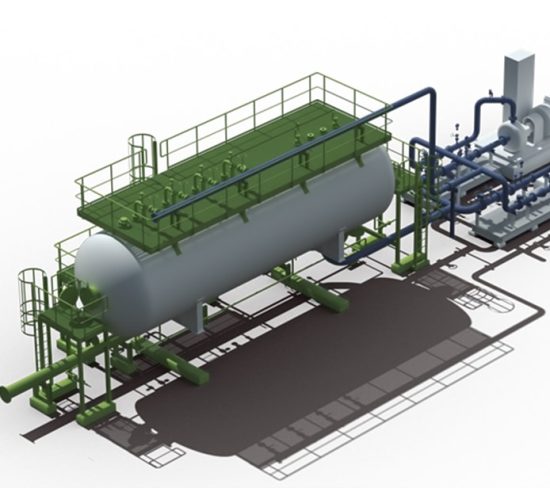

FCC Cyclones – Reactor

Reactor Cyclones are cyclone separators used to separate hydrocarbon vapors and stripping steam from FCC catalyst. Reactor Cyclones are constructed from refractory lined carbon steel or low alloy steel or even stainless steel and come in many different configurations.

Reactor Cyclones can be attached directly to the riser with a second stage following in a closed coupled system or can be open coupled. They can also be a single stage cyclone preceded by a riser termination device.

For over 120 years, Emtrol-Buell has blazed a path to design and build dependable, highly advanced refining equipment. Facilities that use FCC Cyclone Reactors to refine heavy petroleum are employing meticulously designed hardware that surpasses anything else available today. The cutting-edge engineering we use to build processing equipment assures it will be running for years without maintenance. This attention to detail and meticulous workmanship means that Emtrol-Buell can provide peace of mind and ensure the quality of an intricate piece of the petroleum refining process for you.

It is essential that your company meets the most exacting industry standards and employs the most advanced systems to avoid the potential problems that can interrupt the oil refining process. To do that, you should demand the industry best. Emtrol-Buell is a superior force in supplying acclaimed, custom-designed Cyclone systems to refineries and petrochemical plants all over the globe.

Emtrol-Buell produces superior FCC Cyclone models for all stages of the refining process so that your facility can benefit from their industry leading technology expertise from beginning to the end. We can customize our products to suit your specific needs. We build the perfect equipment for any and all refining facilities. When you choose equipment for your refinery’s needs, choose the proven leader that builds more FCC Cyclones for refineries and plants than anyone in the world. You should be proud of the equipment you use. Choose Emtrol-Buell.

FEATURES & BENEFITS

- Enhanced aspect ratio of the cyclone inlet

- New crossover duct design

- Minimized use of edge bars in the refractory linings

- Standard or complex designs

- Dust hopper and lined dipleg stub designs that enhance catalyst discharge while decreasing erosion effects

- Low Total Cost of Ownership

- Maximum performance and efficiency

- High reliability

- Enhanced to increase separation efficiency

- Premium quality material construction to withstand severe operating conditions