OLEFIN Flue Gas Management Systems

Olefin production is one of the highest energy consuming processes in the chemical industry. The core process for olefin production is steam cracking, which converts hydrocarbon feedstocks (naphtha, propane, ethane, etc.) to olefins (ethylene, propylene, etc.) and related products. The worldwide demand and production of olefins are one of the highest compared to other chemicals.

The flue gas management systems integrate a gas turbine within for example an ethylene plant. Process gasses which are partially flared off are used to fire a gas turbine instead. The benefits are independent electric power supply and/or gas compression.

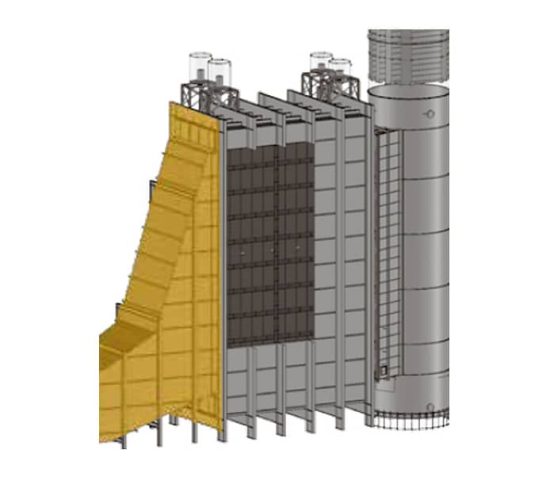

The Integrated Flue Gas Management Systems consist of:

- A gas Turbine sized for your system

- A full system of control valves to assure safe and efficient operation

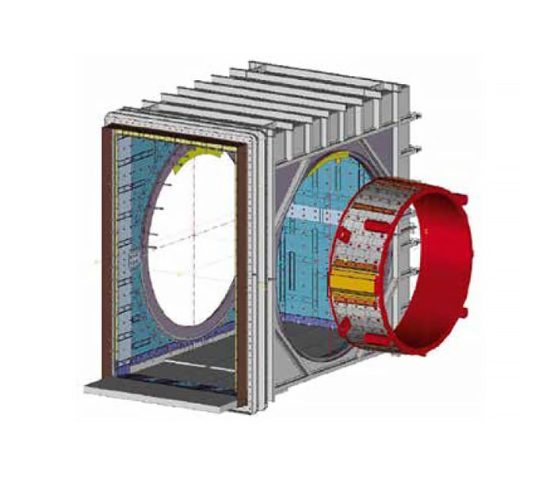

- An air mixing system to ensure correct O2 levels for the burner system

- A Bypass system for stand-alone Gas Turbine Operation

- An emergency air intake system to accommodate stand-alone operation of the heater / process units