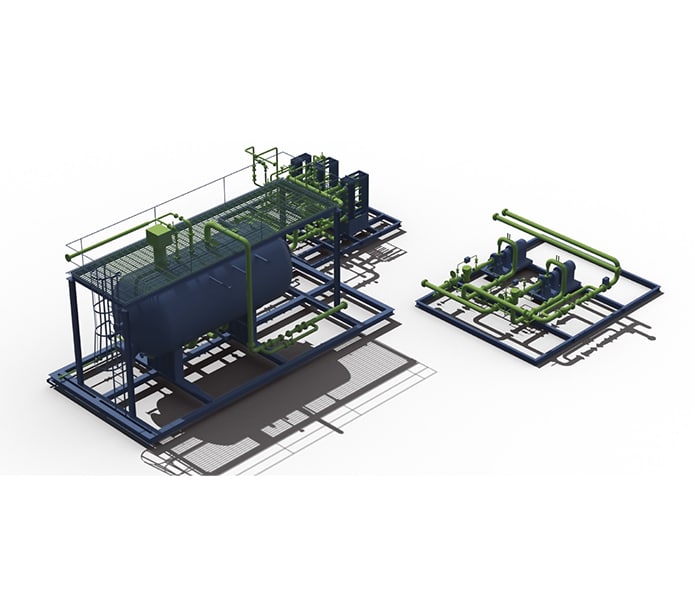

Dehydrator

Peerless Dehydrators are compact Electrostatic Coalescer Units which use a high voltage electrostatic field to coalesce smaller water droplets thus separating them from the Oil phase. Peerless Desalters have been working in the field for more than 20 years and are one of the most trusted technologies for Dehydration and Desalting. Depending on process requirements, Peerless can offer Dehydrator/Desalter units in various configurations including Two Grid or Three Grid Design with single or multiple power units.

The crude oil water emulsion enters the dehydrator unit from a Peerless proprietary designed Inlet Header which ensures even distribution of crude between the grids. The emulsion gets induced either below or between the grids depending upon the selected design to avoid any short circuiting and hassle-free operation of the unit. These grids are charged with high voltage power supply from Power Transformers which are specially designed transformers for this purpose.

High voltage excites water particles to collide and coalesce to form bigger droplets achieving a degree of separation which is much higher than Gravity Separators.

The separated oil is collected from the oil collection header at the top and water is collected from the bottom header.

Desalter

Desalting is an extension of the dehydration process where fresh water is mixed with crude using a mixing valve to create a diluted emulsion and reduce concentration of salt in the water phase. The crude mixed with water is introduced into the desalter vessel where the separation of water and oil also removes the salt which is dissolved in water. Based on the process requirements either Single Stage or Two Stage configuration can be offered.

In a Two Stage Desalter, fresh water is injected in the crude oil upstream of the second stage desalter. The water is mixed with crude oil using a specially designed mixing valve. The brine that leaves from the 2nd stage desalter bottom is pumped to the upstream of the 1st stage mixing valve Desalter. The brine leaving the 1st stage desalter process passes through the wash water heat exchanger where it loses heat to the incoming wash water from the source. The crude from 1st stage flows to 2nd stage desalter.

Features & Benefits

Peerless offers Desalters/Dehydrators designed with state-of-the-art technologies to achieve the most stringent Performance Guarantee requirements in Crude Oil Processing Units or Refineries. These units can meet performance guarantees of 0.1 to 0.5 BS&W and salt Guarantees of down to 5-10 PTB (Pounds Per Thousand Barrel). These units are designed to process crudes ranging from Light Condensate to Heavy Opportunity Crudes.

- Offshore – Mobile Offshore Production units (MOPU)

- Offshore – FPSO Topsides

- Onshore – Oil and Gas Processing Facilities

- Onshore – Early Production Facilities (EPF)

- Refineries & Petrochemical

Dallas, TX, USA

Phone: 214-357-6181

Elma, NY, USA

Phone: 716-662-6540

Stansted, Essex, United Kingdom

Phone: +44-1439-330623

Dubai, United Arab Emirates

Phone: +971 (0) 4434 0004

Singapore

Phone: +65-6472-0020

Shanghai, China

Phone: +86-21-62560387