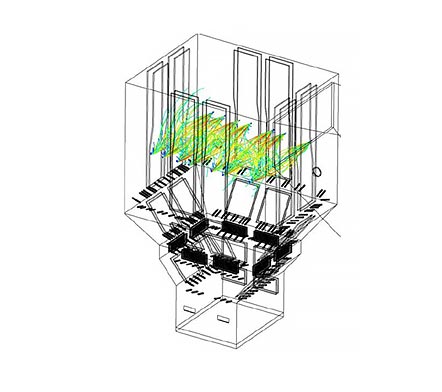

V Series – Oil Absorbing Filter Systems

Our Mefiag V Series – Oil Absorbing Filter Systems are specifically designed for the removal of oil and grease from cleaning solutions, rinse water, wastewater, and other corrosive liquids.

Mefiag was founded in 1953 and has since become a global leader in developing, creating, and distributing unparalleled filter solutions. Our state-of-the-art pump and filtration systems have excelled in the plating, anodizing, and metal finishing industries. Our products handle the most demanding conditions. When the work is hard, Mefiag filters accept the challenge.

Mefiag versatile products reign supreme in the market. In addition to filtration solutions for electroplating, our robust pumps and filters are installed in numerous applications around the world. Companies have come to trust Mefiag products for the filtration and disposal of harmful materials. As our expertise has broadened, our commitment to designing reliable, efficient products for our clients has remained the same. Choose peace of mind by always choosing Mefiag filtration systems for your business.

At Mefiag, we are proud of our long history. We are devoted to delivering exceptional products for exceptional people. If you strive for superiority as hard as we do, then you know you can trust Mefiag to provide the reliability and excellence it deserves. For the optimum filtration solution, choose Mefiag.

FEATURES & BENEFITS

- Operating temperatures to 180° F (82° C)

- Specially designed for the filtration of degreasing baths

- Equipped with a specially designed perforated basket for an optimal contact between the oil absorbing filter material and the liquid

- Can be equipped with a polypropylene slurry tank

- Filter basket has a capacity of 3, 5, 9, or 16 gallons (13.6, 22.7, 40.9, or 72.7 L) depending on the model

- Low Total Cost of Ownership

- Hydrophobic meltdown polypropylene media provides best oil absorbing characteristics as well as large surface area

- The absorption capacity of the oil adsorbing filter material is 1:8-12. (This means that 1 lb. of oil adsorbing filter material can absorb 8 to 12 lbs. of grease and dirt resulting in much longer lifetime of your degreasing baths)

APPLICATIONS

- Automotive

- Construction

- Sanitary

- Plating

- Anodizing

- Metal Finishing

- Labs

- Small Plating Tanks