SERVE YOUR SHIP NOT YOUR LOUVER

ELIMINATE CORROSION IN MARINE ENVIRONMENTS

THE BATTLE AGAINST CORROSION IS CONSTANT. PEERLESS COMPOSITE LOUVERS CAN REDUCE COST, MAINTENANCE AND YOUR SHIP’S RADAR SIGNATURE. PEERLESS PROVIDES AN ALTERNATE APPROACH USING FIBER REINFORCED PLASTIC (“FRP”) COMPOSITE MATERIALS TO ELIMINATE CORROSION ISSUES WHILE MAINTAINING ESSENTIAL PERFORMANCE CHARACTERISTICS.

ELIMINATE CORROSION IN MARINE ENVIRONMENTS

Air intake systems aboard maritime vessels include systems to remove saltwater and airborne particulates from the air that is being transferred into HVAC ventilation or gas turbine combustion air intake ducts. Other types of louvers are utilized to protect workspaces or cargo holds. These systems are typically located within the ship’s hull or on bulkheads that are exposed to weather, bow waves and countermeasure washdown sprays. As such, exposure to a saltwater atmosphere presents a formidable corrosion challenge that requires regular maintenance operations such as grinding, abrasive blasting and re-painting.

Eventually, the corrosion effects become so bad that sections of the equipment must be removed and replaced with costly new base materials or the entire piece of equipment must be replaced. Peerless is an experienced and reliable leader in designing and supplying a wide range of compact, high-efficiency, separation and filtration equipment. Our latest developed louvers use fiber reinforced plastic (“FRP”) composite materials to eliminate corrosion issues while maintaining essential performance characteristics. In certain military shipboard applications, significant new benefits such as radar absorbing “stealth” technology are also incorporated.

BENEFITS OF FRP COMPOSITE LOUVERS

1

SAVES WEIGHT

- Advanced manufacturing techniques are applied to replace traditional welded structures with interlocking parts that are bonded together with epoxy material. These FRP parts can be molded or pultruded to develop shapes with exacting tolerances commensurate with formed steel or extruded aluminum shapes.

2

REDUCE MAINTENANCE TIME

- Our composite louvers are manufactured with a combination of fiberglass and polyester resins, which are found to exhibit low wear, UV resistance and high thermal oxidative stability.

3

INCREASE SURVIVABILITY

- When our fiberglass is combined with a special carbon fiber veil, the resulting FRP composite is extremely lightweight, providing protection against corrosion while at the same time absorbing and/or selectively reflecting electromagnetic radiation.

HOW FRP LOUVERS ARE MADE

Instead of using molded parts where each shape and size is built with a specific mold, an advanced method of “pultrusion” was developed and applied for the US Navy LPD amphibious assault vessels and the Military Sealift Command T-AKE replenishment ships. The pultrusion process is based on the continuous production of woven or non-woven fibers impregnated with resin and pulled through a heated die. As depicted below, this method produces 20-foot-long parts of a consistent cross-section.

The selection of FRP composite base materials focuses on the type of resin and glass fiber used for structural reinforcement. The primary driver for material selection for military shipboard applications is the structural requirement to withstand shock and vibration impacts as qualified per US Navy requirements MIL-S-901D and MIL-STD-167-1, respectively.

Resins are available with different chemical compositions, such as vinyl ester, and the finished parts will be painted to provide a uniform final product that matches the ship’s color. Special paint treatments to create an ice-phobic surface can be used to prevent ice buildup on vessels that are deployed in cold weather conditions. Finally, adding alumina trihydrate to the base resin enables the components to address ASTM-E-162 flame spread, ASTM-E-662 smoke generation, and ASTM-E-1534 time to ignition and heat release requirements specified by the US Navy.

SAVINGS CALCULATOR

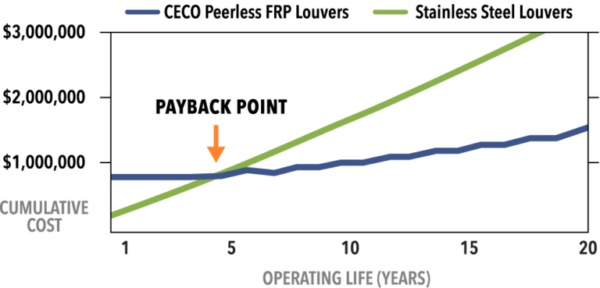

According to feedback from Military Sealift Command Port Engineers, the acquisition cost for a full ship set of thirty-eight new FRP composite louvers for the USN Cesar Chavez (T-AKE-12) was comparable to one maintenance cycle for half a ship set of painted steel louvers. An analysis of full ship set installation and multi-year operating maintenance costs presents an even more compelling argument for FRP composites. This review shows a balance of the initial cost of goods for FRP louvers versus a much higher lifetime cost of maintenance for steel louvers with a payback period of less than five years.

Considering a 20-year operating lifetime and a shipset of thirty T-AKE class louvers of varying sizes, the following assumptions were made:

- 2% annual inflation rate

- New steel louvers would need blast, paint and blade replacements starting in the 3rd year.

- New FRP louvers may not experience corrosion but would require touch-up painting starting after 5 years.

WHY CHOOSE CECO?

WHY CHOOSE CECO?

CECO Environmental is a leading environmentally focused, diversified industrial company whose solutions protect people, the environment, and industrial equipment across the globe, serving a broad landscape of industrial air, industrial water and energy transition markets, including the lithium mining, battery manufacturing and recycling market.

We have over 150 years of innovation and deep application expertise at CECO Environmental. Our heritage dates to 1869, when the Dean Brothers Pump Company was established to solve the world’s high-temperature pumping challenges. One hundred years later, the Claremont Engineering company was founded and became known as CECO Environmental. We now have more than 20 known and trusted companies that have joined the CECO family of brands.

“At CECO we are proud to Win Right by serving our customers, solving real industrial challenges while protecting our most important natural resources.”

—Todd Gleason, CEO

Contact

CLEANER ENERGY,

CLEANER FUTURE

To learn more about these total solutions to improve the environmental performance of your business, fill out the form or click the email button below.